Before

Sealing elliptical wall openings is difficult - they must first be leveled. In addition, there is little space for the work in this corner area. Precise work is required here!

Do you have a question about our offers? Please feel free to contact us via:

+49 (0)7324 96960

info@uga.eu

Find your right contact person for the office or field service here:

Complex installation situations require well thought-out solutions.

Complex installation situations require sophisticated solutions. UGA SYSTEM-TECHNIK is your specialist for custom-made special components, which we manufacture individually for you. What if you have more complex requirements than a standard core bore? These special challenges require special drawings and occupancy tests - which our technicians will be happy to produce for you. We come to your construction site, take measurements and deliver the perfect solution. In this way, we are guaranteed to protect every building against water and gas. You benefit from our many years of experience, unique service and fast delivery times. We support you with your project from planning to implementation.

See for yourself how our high-quality products offer you security. We not only offer products for refurbishment, but also special solutions for new builds.

Click through the picture gallery and find out how we can find the right solution for you.

.png?width=700&height=420&name=UGA-Sonderloesung-Prozess%20(1).png)

With our team of technical consultants, we offer you on-site advice for custom-made special components. Our strength lies in solving challenging installation situations. We come to you, take measurements and deliver the perfect product for your individual requirements. You can rely on our experience and service to protect your building from water and gas. Together we will master your challenges.

.png?width=700&height=420&name=UGA-Sonderloesung-Prozess%20(2).png)

Direct solutions are our specialty at UGA. Our team starts designing your individual products immediately. Thanks to our flexibility and experience, we implement any necessary adaptations immediately. Our design team and production work hand in hand in close cooperation - so that everything fits perfectly for you in the end.

.png?width=700&height=420&name=UGA-Sonderloesung-Prozess%20(3).png)

Quality and efficiency are at the heart of our production at UGA. Throughout the entire production process, we use effective quality management to ensure that every product meets our high standards. Our in-house production with certified welders enables us to manufacture products of the highest quality.

.png?width=700&height=420&name=UGA-Sonderloesung-Prozess%20(4).png)

Thanks to the fast and efficient production process, you are guaranteed to receive your products when you need them. We also make sure that your products arrive at exactly the right place. Our supply chain is optimized to avoid long waiting times or unnecessary delays. And to ensure that everything runs smoothly, we can advise and assist with installation if required. Or you can leave this step to us and our installation service. Our top priority is to make your process as simple and efficient as possible.

Before

Sealing elliptical wall openings is difficult - they must first be leveled. In addition, there is little space for the work in this corner area. Precise work is required here!

Afterwards

We also offer you suitable solutions for difficult installation situations. This corner construction with one partition can also be installed where space is limited.

Special features

Assembled products

Before

In this renovation case, corrugated cable protection pipes had already been routed through a masonry wall. These are partially torn off, leaky and therefore a safety risk for the building. The non-flat surface of the wall is particularly challenging.

Afterwards

The split adhesive / filler flange is ideal as a solution for penetrations within the black tray without losing its watertight properties.

Special features

Assembled products

Before

Rigidly installed cable protection conduits with defined axial dimensions.

Afterwards

The individual sealing insert is ideal as a solution for feed-throughs within the black tray without losing its watertight properties.

Special features

Assembled products

Before

Not an easy task: many cables are fed underground here, which have to be rearranged and sealed according to the installation levels.

Afterwards

The custom-made special component not only seals all cables perfectly and organizes them. It also leaves space for easy and safe re-routing of future cables - a saving on further work.

Special features

Assembled products

This product is ideal for warm roofs. Thanks to the variable sealing levels, it adapts flexibly to your needs. You can easily adjust the height. This is particularly practical if the thickness of the thermal insulation is not yet known. Take advantage of this flexibility for your building.

Every rigid cable and pipe requires an individual solution to guide it through your roof. Our double flange constructions with angled sockets are designed precisely for this purpose and adapt perfectly to any bending radius. No matter what diameter, number and angle you need - we will tailor it to your requirements.

Do a large number of cables need to be routed through a roof in a small space? No problem. We adapt the number, arrangement and diameter of each individual cable perfectly to your specific construction situation.

Rigid cables in the tightest of spaces with individual roof openings? Our variable and square second sealing level adapts perfectly to your requirements. We also offer matching square rubber press seals.

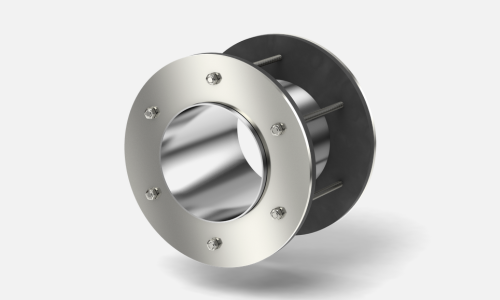

Our special lining pipe with counter flange enables an above-ground feed-through, which can also be retrofitted if required. Thanks to the clever use of the counter flange, the components can be pressed from both the inside and the outside. This ensures optimum tightness. A particularly practical feature of this component is that it can also be fixed in place without welding.

When it comes to protection against vandalism or theft, our solutions are extremely secure. As threaded rods and nuts, i.e. all connecting elements, are on the inside, they cannot be removed from the outside. This provides optimum protection for your construction.

Reliably protect values

Our technical consultants in the field are at your side - directly at your construction site, anywhere in Germany .

Contact us

No problem - just get in touch with us!

UGA SYSTEM-TECHNIK GMBH & CO. KG

Heidenheimer Str. 80-82

89542 Herbrechtingen

Germany