Wallsleeve for retrofitting - FU-NA

Discover the perfect waterproofing solution for your construction projects with our versatile FU-NAs! Find out more about our individual solutions and be inspired by a real-life construction site example in which our specially adapted FU-NA proved its full capabilities.🙌🏽

What is a FU-NA? 🤔

Our FU-NA is your solution for wall sleeves with flexibility and adaptability for any type of renovation! Our FU-NA shines with a perfect seal, especially for sealing masonry!

FU-NA stands for casing pipes for retrofitting and offers a wide range of variants to meet your needs:

🔧 With fixed and loose flange construction for robust installations that meet the requirements of DIN 18533 for sealing against pressing water (W2) or non-pressing water (W1).

🔧 With adhesive flanges for easy installation and flexibility when waterproofing in accordance with DIN 18533 for moderately pressing water (W2.1) and non-pressing water (W1) using liquid waterproofing materials.

🔧 With front flange for specific requirements for concrete structures made of waterproof concrete.

Whether you are dealing with non-pressing water, moderately pressing water or pressing water, FU-NA offers the right solution for your requirements! Our products are ideal for various applications.

The best thing about it? Our products are customizable to meet your exact requirements

To give you a better idea of one of our FU-NA's, here is an example of an actual initial situation on a construction site!

In this construction project, we were faced with the challenge of sealing a masonry structure with openings. The pipes that had already been laid could not be sealed with our standard rubber press or ring-space seals. We therefore had to find a special solution to safely seal the construction site.

Before we could install our sealing solution, it was necessary to repair and straighten the wall structure and repair the damaged pipes. We relied on our tried-and-tested GPD with 60 mm EPDM rubber to seal the cable conduits. Thanks to the high-quality EPDM rubber compound and low tightening torque, we were even able to successfully seal sensitive cable protection pipes without demolishing them. In addition, a further layer of bitumen thick coating was applied to the wall and flange to ensure the tightness of the entire wall structure.

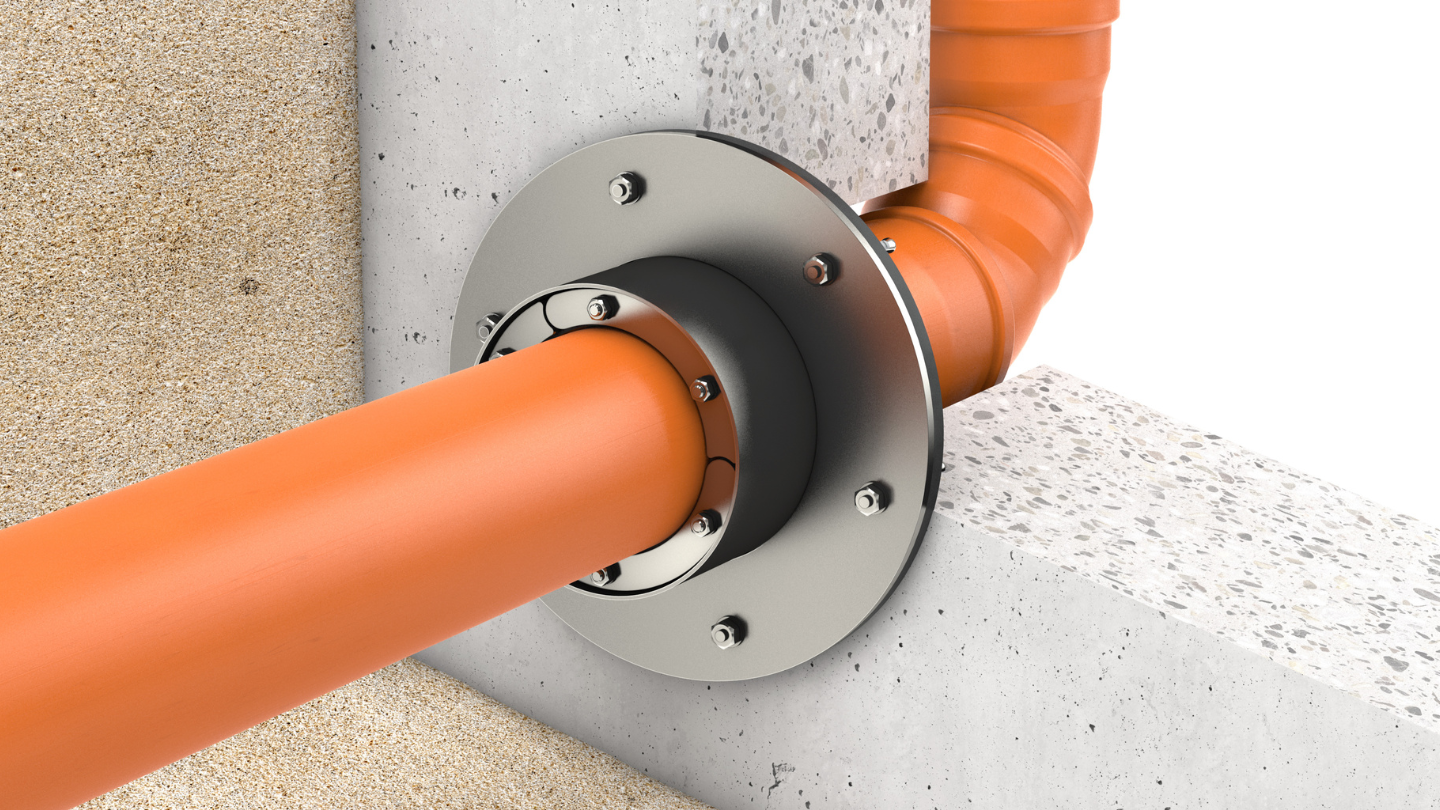

This was followed by the installation of the sealing solution from UGA! An adapted FU-NA was fitted here, which seals to the wall. The matching sealing inserts then seal the FU-NA, cables and cable protection pipes.

In the end, everything was sealed 🙌🏽

Do you need help choosing the right duct? Please contact your personal Contact person in the field service!

.png?width=201&height=92&name=UGA-Logo-EN(1).png)